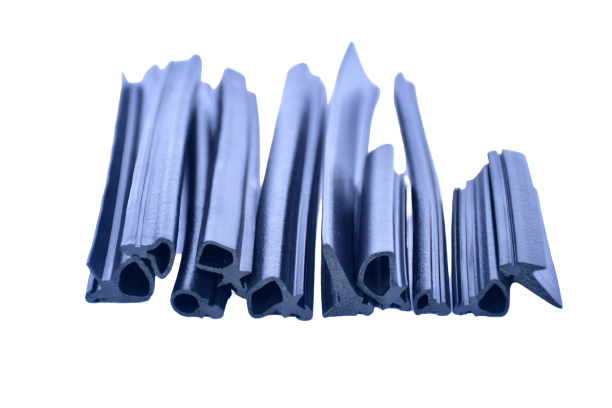

Why EPDM?

EPDM (Ethylene Propylene Diene Monomer) is a synthetic rubber material known for its excellent properties, making it suitable for various industrial and automotive applications. Here are some key properties and typical values of EPDM:

| Properties | Value / Value Range(Solid Part) | Properties | Value / Value Range(Solid Part) |

|---|---|---|---|

| Weather Resistance | Excellent | Chemical Resistance | Excellent resistance to acids, alkalis, and polar solvents Moderate resistance to non-polar solvents and oils |

| UV Resistance | Excellent | Compression Set | Low compression set, retaining its shape after compression and rebounding effectively |

| Ozone Resistance | Excellent | Water Resistance | Excellent water resistance and impermeability |

| Outdoor Weathering | Excellent | Electrical Insulation | Good electrical insulating properties |

| Temperature Range | Tensile Strength | 10-20 MPa (1450-2900 psi) | |

| Continuous Use Temperature | -40°C to +120°C (-40°F to +248°F) | Elongation at Break | 200%-600% |

| Short-Term High-Temperature Resistance | Up to +150°C (+302°F) | Tear Resistance | Excellent tear resistance |

| Flame Resistance | Self-extinguishing and resistant to flame spread | Hardness | 40-90 (depending on the formulation) |

| Low-Temperature Flexibility | Remains flexible at low temperatures | Abrasion Resistance | Good resistance to abrasion and wear |

EPDM's outstanding properties, such as weather resistance, flexibility, and chemical resistance, make it widely used in applications like automotive seals, weatherstripping, roofing membranes, gaskets, hoses, and various outdoor and industrial components. The specific values of these properties may vary depending on the specific grade, formulation, and manufacturing process of the EPDM material. For precise data, it is recommended to refer to technical data sheets provided by EPDM manufacturers.